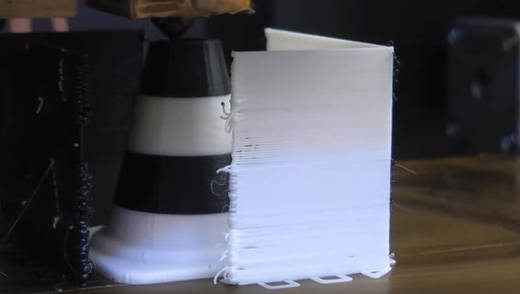

The one I did below is slightly over exposed as you can tell from the rectangles at the bottom.

This allows you to print a 5-minute model that has small details that show whether you are under exposed, have a good exposure or over exposed. I’d recommend increasing your normal exposure times to fix resin prints that crack or split.Īn important thing to do before you even start printing your models is to dial in your exposure time settings using something like a Resin Validation Matrix V2. You want to avoid these potential small fractures throughout the printing process. You may even get supports that don’t print all the way due to a low normal exposure. When your exposure time is too low, you’ll experience under-exposure which can lead to flimsy or low detail parts.ĭepending on your specific model, it can lead to splits or cracks due to essential parts of the print not being strong enough to hold the weight of the model. I created a hole in this hulk model, so resin can drain out and not cause cracks or splits.Īnother key part of part strength is your normal exposure time. It’s a good thickness where it is more likely to be durable rather than some thin walls. You can see the walls below which is the white parts, while the hollowed part is the black parts in the middle. The minimum wall thickness I would use is 2mm, increasing this to 2.5-3mm for parts that may need sanding or that I want more strength with. Your wall thickness is one of the key factors to increasing the durability of your prints, so I’d make sure to use a good wall thickness. The strength of the model itself comes into play when models crack or split. Next, I’ll give it an extra wash by using a toothbrush so I can get it almost squeaky clean to reduce any white marks or residue on the model afterwards.Īs long as you ensure any resin and cleaning solution is drained from your model, it should help fix models that crack or split. After the model is clean, I’ll remove the supports and try to clean up some of the marks.

I’ll usually clean most models for a minimum of 2 minutes, up to around 5 minutes for larger models. It has an in-built ultrasonic cleaner which I filled with IPA.

#SIMPLIFY 3D CRACK CLEAN PLUS#

I use the Elegoo Wash & Cure Plus to wash my resin models.

#SIMPLIFY 3D CRACK CLEAN HOW TO#

Clean Out Prints Thoroughly & Drain LiquidĪfter you learn how to hollow your models in your chosen slicer, you want to ensure that the cleaning process is done to a high standard.Ĭleaning out your resin prints thoroughly is important, as well as draining out all the liquid. I’ve even heard that IPA may be able to evaporate and expand leading to failures.Ģ. You want at least one off them to be facing downwards towards the resin vat.Įnsure your drain holes are large enough and in the right locations. Pay attention to where the drain holes are in relation to the build plate because drain holes that point towards the build plate won’t help it leak out so great. You want to try and add more than one drain hole because one is to relieve pressure, then the other to drain the resin out. Preparing a resin print does require attention to detail to figure out where resin can get stuck, then adding a large enough drain hole to make sure it gets out.Ī drain hole of 3mm usually works out fine for a normal-sized resin model. Once your hollow out your models, you want to learn where and how to place adequate drain holes to ensure resin doesn’t get trapped inside.

#SIMPLIFY 3D CRACK CLEAN FULL#

Hollowing your models removes the inner material, leaving just the exterior or the walls around your model.Ī lot of the time, your prints don’t need to be full of cured resin, so you can save resin in the long-run. One of the first things you want to do to fix resin 3D prints that crack or split is to properly hollow your models. Hollow Out Prints with Adequate Drain Holes How to Fix Resin 3D Prints That Crack or Split 1. Now that you have a better idea on why your resin 3D prints might split or crack, let’s get into the ways you can potentially fix this problem. Part orientation is leading to weakness in areas.Using a low quality, water-washable resin.Submerging the print in isopropyl alcohol (IPA) for too long.Not having enough drain holes or them not being large enough.To make things simpler, I listed a number of reasons why a resin print may crack or split: This is why you may see uncured resin leaking from these same cracks. This leads to an increase in pressure inside the model which, over time, can end up splitting the model and potentially popping. Photopolymer resin or 3D printing resin goes through an exothermic reaction which means it gives off heat and expands as it cures. The most common reason for cracks or splits in resin prints is from uncured resin being left inside the model. Drill Holes into Model to Drain Resin Why Do Resin Prints Crack or Split?

0 kommentar(er)

0 kommentar(er)